Visual Appeal and Design of Quarter Sawn Oak Cabinet Doors

Quarter sawn oak, with its distinctive visual characteristics, offers a unique aesthetic for cabinet doors, elevating the overall look of any kitchen or room. The precise cutting method results in a striking grain pattern and contributes significantly to the overall design impact. This detailed examination will explore the visual appeal of quarter sawn oak cabinet doors, comparing them to other popular wood choices and showcasing their versatility across various door styles.

Quarter Sawn Oak Grain and its Aesthetic Impact

The defining feature of quarter sawn oak is its prominent, straight, and tightly spaced vertical grain lines. This linear pattern creates a sense of elegance and sophistication, contrasting sharply with the more varied and often less predictable patterns found in plain sawn oak. The tight grain also contributes to the wood’s durability and resistance to warping, making it a practical choice for cabinet doors that experience regular use. The straight grain pattern also lends itself well to staining and finishing techniques, allowing for a wide range of color and sheen variations. The resulting visual effect is often described as clean, classic, and timeless.

Visual Comparison of Quarter Sawn Oak with Other Wood Types

The visual impact of quarter sawn oak cabinet doors is significantly influenced by its unique grain structure and color compared to other wood species. A direct comparison highlights these distinctions:

| Wood Type | Grain Pattern | Color Variations | Overall Aesthetic |

|---|---|---|---|

| Quarter Sawn Oak | Straight, tightly spaced vertical lines | Light to medium brown, often with subtle variations in tone | Classic, elegant, sophisticated, durable |

| Plain Sawn Oak | More varied, often with cathedral-like figures; less consistent | Similar color range to quarter sawn, but potentially with more pronounced variations | Rustic, natural, less formal than quarter sawn |

| Cherry | Moderate grain, often with subtle figure | Ranges from light reddish-brown to a deep, rich brown, often darkening with age | Warm, rich, traditional; often associated with more formal settings |

| Maple | Fine, even grain; minimal figure | Light to medium tan, often with a subtle creamy hue | Clean, contemporary, light and airy; can be both formal and informal |

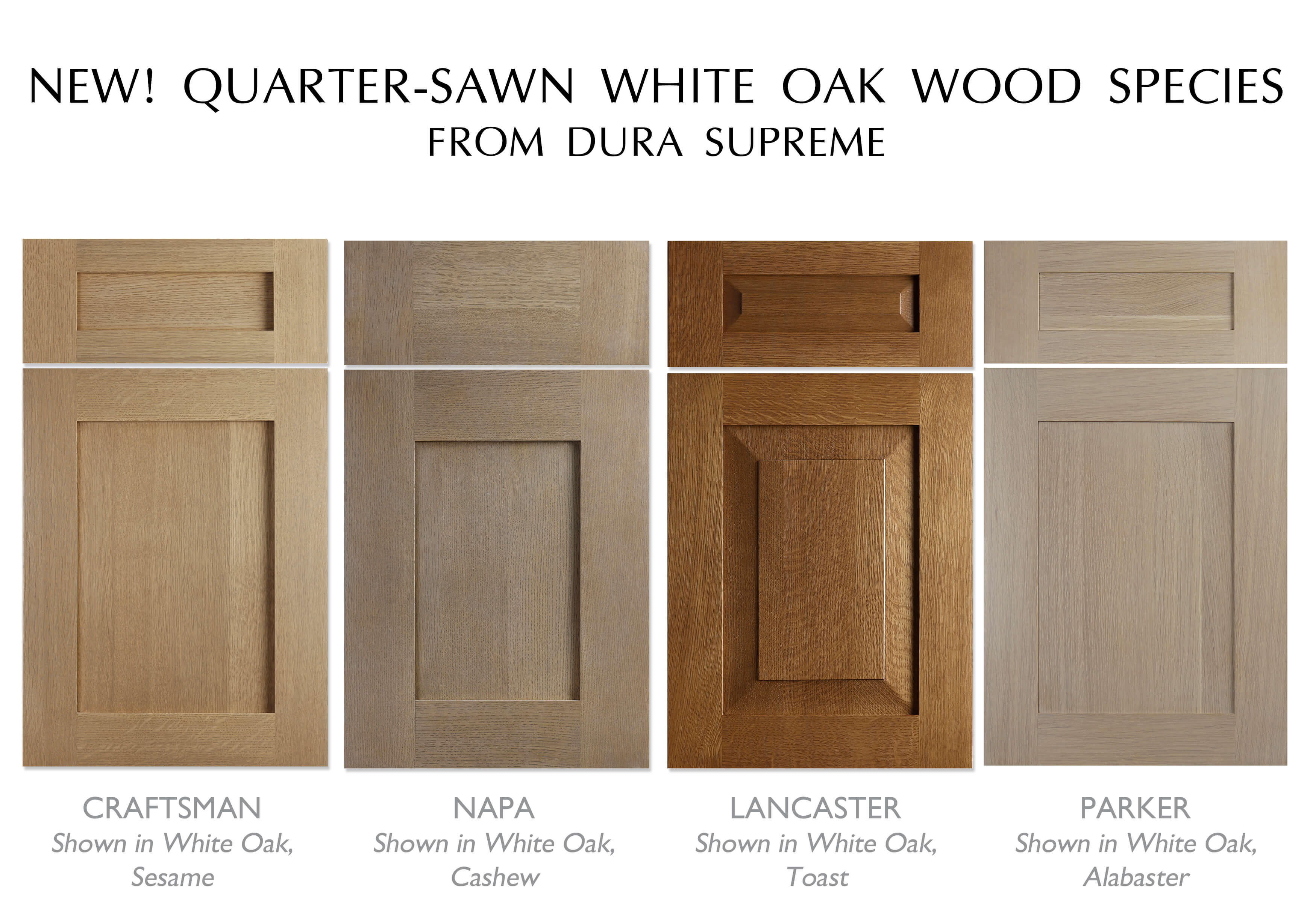

Quarter Sawn Oak Cabinet Door Styles

Quarter sawn oak’s versatility allows it to be used in a wide range of cabinet door styles. Each style contributes a different visual character to the overall design.

Shaker style doors, with their simple, flat panels and clean lines, showcase the beauty of the wood grain without distraction. The straight grain of quarter sawn oak complements the Shaker’s minimalist aesthetic perfectly. Raised panel doors, featuring a recessed central panel framed by a raised border, allow the quarter sawn oak’s grain to be highlighted both within the recessed panel and in the surrounding frame, adding depth and visual interest. Flat panel doors offer a sleek, modern aesthetic; the consistent grain of the quarter sawn oak enhances this clean look. The straight grain pattern contributes to a feeling of order and sophistication in this style. The subtle variations in color within the quarter sawn oak add a touch of warmth and visual complexity to the otherwise simple design.

Manufacturing and Construction Techniques for Quarter Sawn Oak Cabinet Doors

The creation of high-quality quarter sawn oak cabinet doors involves a precise process, from the initial selection and cutting of the lumber to the final finishing touches. Understanding the manufacturing techniques is crucial for appreciating the superior durability and aesthetic appeal these doors offer compared to other options. The unique properties of quarter sawn oak, stemming directly from its cutting method, directly influence the final product’s characteristics.

The process of quarter sawing oak lumber involves cutting the log radially, perpendicular to the growth rings. This method, unlike plain sawing, results in a more stable and visually striking wood grain pattern with distinctive, tightly spaced vertical lines. The tighter grain structure significantly enhances the wood’s resistance to shrinkage and warping, contributing to the exceptional durability of quarter sawn oak cabinet doors. The characteristic fleck or “ray” pattern also creates a visually appealing, classic look that is highly valued in fine cabinetry. This process minimizes the likelihood of cupping or twisting, ensuring the dimensional stability of the finished product over time. The distinct grain pattern adds a touch of elegance and sophistication that is difficult to replicate with other wood types or sawing methods.

Quarter Sawing Oak Lumber and its Impact on Durability and Appearance

Quarter sawing oak significantly impacts the final product’s characteristics. The radial cut exposes the medullary rays, creating the characteristic fleck or ray pattern visible on the surface of the wood. This not only enhances the visual appeal but also contributes to the wood’s stability. The tighter grain structure inherent in quarter sawn oak reduces the likelihood of shrinkage and warping, leading to increased durability and longevity of the cabinet doors. The resistance to moisture movement is considerably higher compared to plain-sawn oak, making quarter sawn oak an ideal choice for cabinet doors, which are often exposed to changes in humidity. Furthermore, the increased density resulting from the quarter sawing process makes the doors more resistant to dents and scratches.

Solid Wood versus Veneer Construction Methods

The choice between solid wood and veneer construction significantly affects the cost, durability, and aesthetic qualities of quarter sawn oak cabinet doors. Both methods have their own advantages and disadvantages.

Quarter sawn oak cabinet doors – The following table compares the two construction methods:

| Feature | Solid Wood Quarter Sawn Oak Doors | Veneer Quarter Sawn Oak Doors |

|---|---|---|

| Cost | Higher | Lower |

| Durability | Very High; Resistant to damage and warping | Moderate; Susceptible to damage if veneer is compromised |

| Appearance | Superior; consistent grain pattern throughout | Good; can replicate the look of solid wood but may show inconsistencies |

| Weight | Heavier | Lighter |

| Maintenance | Requires regular maintenance to preserve finish | Requires careful handling to avoid damage to veneer |

Constructing a Raised Panel Quarter Sawn Oak Cabinet Door, Quarter sawn oak cabinet doors

Creating a raised panel quarter sawn oak cabinet door involves precise joinery and finishing techniques. The following steps Artikel the process:

- Prepare the Stiles and Rails: Cut the stiles and rails to the desired dimensions, ensuring accurate measurements for a perfect fit. The choice of wood should be high-quality, properly dried quarter sawn oak to minimize warping and shrinkage.

- Cut the Panel: Cut the raised panel to fit snugly within the frame. The panel should be slightly smaller than the opening to allow for expansion and contraction.

- Create the Raised Panel Profile: Use a router and appropriate bits to create the desired raised panel profile on the panel. A consistent depth and smooth surface are crucial for a professional finish.

- Join the Stiles and Rails: Use mortise and tenon joinery for a strong and durable connection. Precisely cut the mortises and tenons to ensure a tight fit. Glue and clamps are essential to secure the joints.

- Assemble the Frame: Assemble the frame, ensuring the stiles and rails are square and aligned. Use clamps to hold the frame together while the glue dries.

- Install the Panel: Carefully install the raised panel into the frame. Ensure a tight fit to prevent movement. Glue may be used to secure the panel, depending on the desired level of permanence.

- Sanding and Finishing: Sand the entire door thoroughly, starting with coarser grit sandpaper and gradually moving to finer grits. Apply several coats of finish, allowing each coat to dry completely before applying the next. The finish should protect the wood from moisture and enhance its natural beauty.

Cost, Maintenance, and Longevity of Quarter Sawn Oak Cabinet Doors

The inherent value and lasting appeal of quarter sawn oak cabinet doors are closely tied to their cost, the ongoing maintenance they require, and their impressive longevity. Understanding these factors is crucial for homeowners and designers alike, informing both budget allocation and long-term planning. This section will delve into the multifaceted aspects of cost drivers, maintenance strategies, and the expected lifespan of these high-quality cabinet doors.

Factors Influencing the Cost of Quarter Sawn Oak Cabinet Doors

Several key factors contribute to the overall cost of quarter sawn oak cabinet doors. These factors interact to create a price range that can vary significantly depending on the specific project requirements. Ignoring any of these can lead to inaccurate budgeting.

Wood quality plays a dominant role. The grade of the oak, its density, the presence of knots and other natural imperfections, and the overall consistency of the grain all impact price. Premium, clear-grained oak commands a higher price than oak with more visible character marks. Similarly, the thickness of the wood itself affects cost; thicker doors are more expensive.

Door style and design significantly influence cost. Simple, shaker-style doors are generally less expensive to produce than ornate, raised-panel doors with intricate detailing. Intricate carvings, custom molding, and complex joinery all add to the labor costs, and thus the final price.

Size and quantity are also important cost drivers. Larger doors naturally require more material and labor, increasing the cost proportionally. Ordering a large quantity of doors often allows for economies of scale, resulting in a lower per-unit cost. Conversely, bespoke, custom-sized doors will always command a premium.

Finally, the manufacturing process itself plays a part. Hand-crafted doors, made using traditional techniques, are substantially more expensive than those produced using automated processes. The level of finishing – from a simple stain to a multi-step process including hand-rubbed oils – will also affect the final price.

Maintenance Requirements for Quarter Sawn Oak Cabinet Doors

Proper maintenance is essential to preserve the beauty and longevity of quarter sawn oak cabinet doors. A proactive approach can prevent damage and ensure the doors remain a stunning feature of your kitchen or bathroom for years to come.

Regular cleaning is paramount. A soft, damp cloth is usually sufficient for routine cleaning. Avoid harsh chemicals and abrasive cleaners that can damage the finish. For stubborn stains, use a mild soap solution and always rinse thoroughly.

Avoid using excessive water or allowing moisture to penetrate the wood, as this can lead to warping or damage.

Protecting the finish is crucial. Periodically applying a suitable wood conditioner or furniture polish will help to maintain the luster and protect the wood from dryness and cracking. Always follow the manufacturer’s instructions for the specific product used.

Regularly inspect the doors for any signs of damage, such as scratches or dents. Address minor issues promptly to prevent them from becoming more significant problems.

Repairing minor damage is often straightforward. Small scratches can be buffed out with a fine-grit sandpaper and appropriate wood filler. For more significant damage, consult a professional woodworker or cabinetmaker.

Lifespan and Longevity of Quarter Sawn Oak Cabinet Doors

Quarter sawn oak, renowned for its exceptional durability and resistance to wear, offers a considerably longer lifespan than many alternative cabinet door materials. Unlike some softer woods or engineered materials prone to scratching, denting, or warping, quarter sawn oak possesses inherent strength and stability.

Compared to materials like medium-density fiberboard (MDF) or particleboard, which are susceptible to moisture damage and are less durable, quarter sawn oak exhibits significantly greater longevity. Even compared to other hardwood species, oak’s density and tight grain structure contribute to its superior resistance to impacts and daily wear and tear. Many well-maintained oak cabinets last for generations, with careful upkeep.

A well-maintained set of quarter-sawn oak cabinet doors can easily last 50 years or more, often surpassing the lifespan of the entire kitchen or bathroom itself. This longevity translates to a significant long-term value proposition, making the initial higher investment worthwhile for homeowners prioritizing quality and durability.